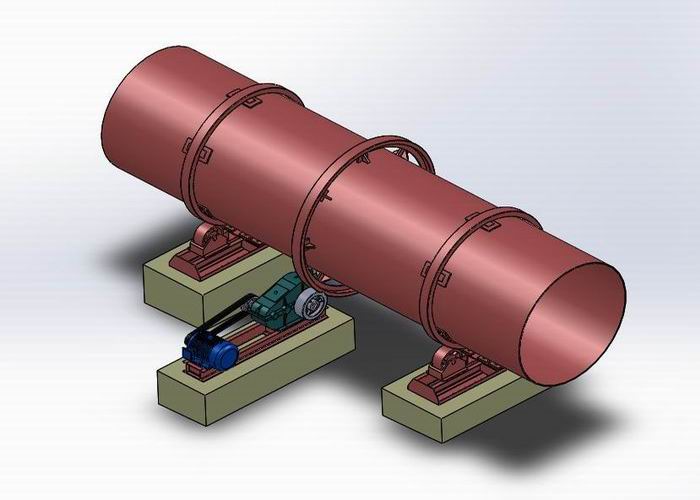

Rotary Compound Bacriminta Granulator

Rotary Compound Bacriminta Granulatorwaa mid ka mid ah qalabka muhiimka ah ee warshadaha bacriminta isku dhafan.Habka ugu muhiimsan ee shaqada waa higaada leh granulation qoyan.Iyada oo loo marayo qaddar gaar ah oo biyo ah ama uumi ah, bacriminta aasaasiga ah ayaa si buuxda kiimiko ahaan looga falceliyaa dhululubada ka dib marka la qoyo.Marxalad dareere ah oo gaar ah, dhaqdhaqaaqa wareega ee foosto ayaa loo isticmaalaa in lagu sameeyo cadaadiska ka saarista walxaha kubbadaha.oo dhanNPK Compound granulation bacriminta khadka wax soo saarkawaxaa ka mid ah:

Mashiinka waxa loo qaybin karaa shan qaybood:

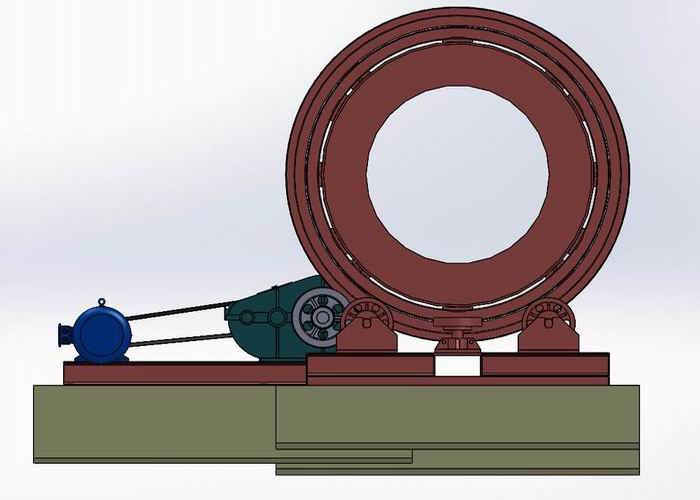

1) Qaybta garabka: dhammaan jidhka qaybta jidhka ee taageerada garabka, xoogga ayaa ka weyn.Sidaa daraadeed qaybaha mashiinka giraangiraha ah waxaa loo isticmaalaa saxanka birta kaarboon, oo lagu dhejiyay kanaalka, iyo iyada oo loo marayo xakamaynta tayada adag iyo shuruudaha Habraaca gaarka ah, ayaa gaadhay ujeedada isticmaalka mashiinka.Waxa intaa dheer in ka badan oo muhiim ah waa go'an on khaanadaha daryeelka, ay sabab u tahay in la tixgeliyo ay duudduuban jirkeeda yeelan doonaan khilaaf weyn, Waxaan beeraa si gaar ah loo doortay anti-daxalka tayo sare leh, xirtaan u adkaysta alaabta, si weyn u hagaajinaya nolosha Mashiinka, Midka kale waxa kale oo loo isticmaalaa in lagu shubo mid ka mid ah afarta dhinac ee giraangiraha oo leh jillaab laadlaadsan, si fudud u rarista iyo dejinta gaadiidka.

2) Qaybta gudbinta: dhammaan qaybta wadista granulator-ka ayaa aad ugu fiican dhammaan jidhka shaqada oo dhan waxay leeyihiin khadkan.Qaabka gudbinta wuxuu ka samaysan yahay bir alxan oo tayo sare leh, iyo iyada oo loo marayo shuruudaha tayada adag.Ku rakib qaabka gudbinta Matoorka ugu weyn iyo yareeyaha ayaa la doortay alaabada ka-dhaafitaanka qaranka ee ISO, tayada la isku halayn karo.Motor kaxeeyaa jiidi, V-suunka, gudbinta reducer in dunidii, si uu jidhku u shaqeeyo, kaas oo kaxeeya reducer in qaybta dunidu ee shaqada, isticmaalka naylon qori off wejiga Xidhiidhiyaha qaniinyada Transfer Drive.

3) Gear Large: go'an on jidhka, iyo pinions gear ilkaha gudbinta, ka soo horjeeda drive shaqada jidhka, isticmaalka qalabka-technoolajiyada sare xirashada u adkaysta, si mishiinka cimri dheer.

4) Roller: go'an labada dhinac ee jirka si ay u taageeraan jirka oo dhan.

5) Qaybta jidhka: guud ahaan granulator-ku waa qaybta ugu muhiimsan ee jidhka, kaas oo ka samaysan saxan bir kaarboon oo tayo sare leh, oo lagu dhex dhisay caag gaar ah ama caag bir ah oo aan adkaysin, si loo gaaro nabarro toos ah, oo ka baxa burada , baabi'inta qalabka qashinka ee dhaqameed, iyo iyada oo loo marayo xakamaynta tayada adag iyo shuruudaha habka gaarka ah si loo gaaro ujeedada mashiinka loo isticmaalo.

1. Heerka granulate-ku waa ilaa 70%, kaliya qadar yar oo soo-noqosho ah, soo celinta xajmi yar oo sheyga ah, mar kale ayaa la granulated karaa.

2. Ku rid kuleyliyaha uumiga, hagaaji heerkulka walxaha, walxaha kubbadda ka dib marka biyuhu hooseeyaan, hagaajiyaan waxtarka qalajinta;

3. oo leh caag injineernimada caag ah oo loogu talagalay dahaarka, alaabta ceeriin ma fududa in lagu dhejiyo, oo ay door ka ciyaaraan ka hortagga daxalka;

4. Wax soo saarka weyn, isticmaalka tamarta yar, kharashka dayactirka hooseeya.

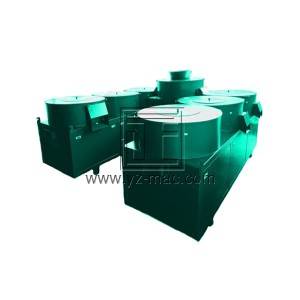

Bacriminta isku dhafka ah waxaa soo saaray granulation durbaanka.Bacriminta isku dhafan waxay siin kartaa nafaqeynta dalagyada hab dhan walba ah.Habka ayaa ah in si kiimiko ah loo soo saaro nafaqooyinka ugu muhiimsan (sida N, P, K iyo walxaha kale ee raadraaca) ee ay u baahan yihiin dalagyada, oo leh nitrogen, fosfooraska, potassium iyo walxo kale oo kiimiko ah oo ku habboon beerashada dalagga dalagga, ka dibna iyada oo loo marayo codsiga dalagga gudaha. ciidda.Nafaqooyinka ka nuugo ciidda.Mabda'a geeddi-socodka waxaa ka mid ah nitrogen, fosfooraska, qaybaha potassium, qaybaha ammonium sulfate, qaybaha calcium hydrogen phosphate iyo qaybaha bacriminta isku dhafan: marka hore, bacriminta fosfooraska (cilmi ahaan loo yaqaan "calcium superphosphate") ayaa la isku daray;Qalab cayriin budo ah oo kala duwan ayaa la granulated, engejiyey oo la qaboojiyey si ay u soo saaraan bacriminta isku dhafan.Habka teknoolajiyada ee line-soosaarka bacriminta isku dhafan waxaa loo qaybin karaa qayb ka mid ah alaabta ceeriin, qaso alaabta ceeriin, granulation alaabta ceeriin, qalajinta qayb, qaboojinta qayb, darajo qayb, daahan alaabta dhammeeyey iyo baakadaha alaabta final.

|

Qaabka | Silinder | Awood | Miisaanka | Matoorka | ||||

| Dhexroorka gudaha | Dhererka | Degree Jiirada

| Xawaaraha wareega | Qaabka | Awood | |||

| mm | mm | (°) | r/min | t/h | t | Qaabka | kw | |

| YZZLZG-1240 | 1200 | 4000 |

2-5 | 17 | 1-3 | 2.7 | Y132S-4 | 5.5 |

| YZZLZG-1450 | 1400 | 5000 | 14 | 3-5 | 8.5 | Y132M-4 | 7.5 | |

| YZZLZG-1660 | 1600 | 6000 | 11.5 | 5-8 | 12 | Y160M-4 | 11 | |

| YZZLZG-1870 | 1800 | 7000 | 11.5 | 8-10 | 18 | Y160L-4 | 15 | |

| YZZLZG-2080 | 2000 | 8000 | 11 | 8-15 | 22 | Y180M-4 | 18.5 | |

| YZZLZG-2280 | 2200 | 8000 | 10.5 | 15-20 | 28 | Y180L-4 | 22 | |