Groove Type Composting Turner Mashiinkawaa mashiinka halsano hawada hawada ee ugu isticmaalka badan iyo qalabka rogid compost.Waxaa ka mid ah shelf jeexdin, jidka socodka, qalabka aruurinta korontada, qeyb ka noqoshada iyo qalabka wareejinta (badanaa loo isticmaalo shaqada taangiyada badan).Qaybta shaqada ee mishiinka leexashada compost waxay qabataa gudbinta rullaluistemadka horumarsan, kaas oo la qaadi karo oo aan la qaadi karin.Nooca la qaadi karo waxaa inta badan loo adeegsadaa xaaladaha shaqada oo leh ballac leexin oo aan ka badnayn 5 mitir iyo qoto dheer oo leexasho ah oo aan ka badnayn 1.3 mitir.

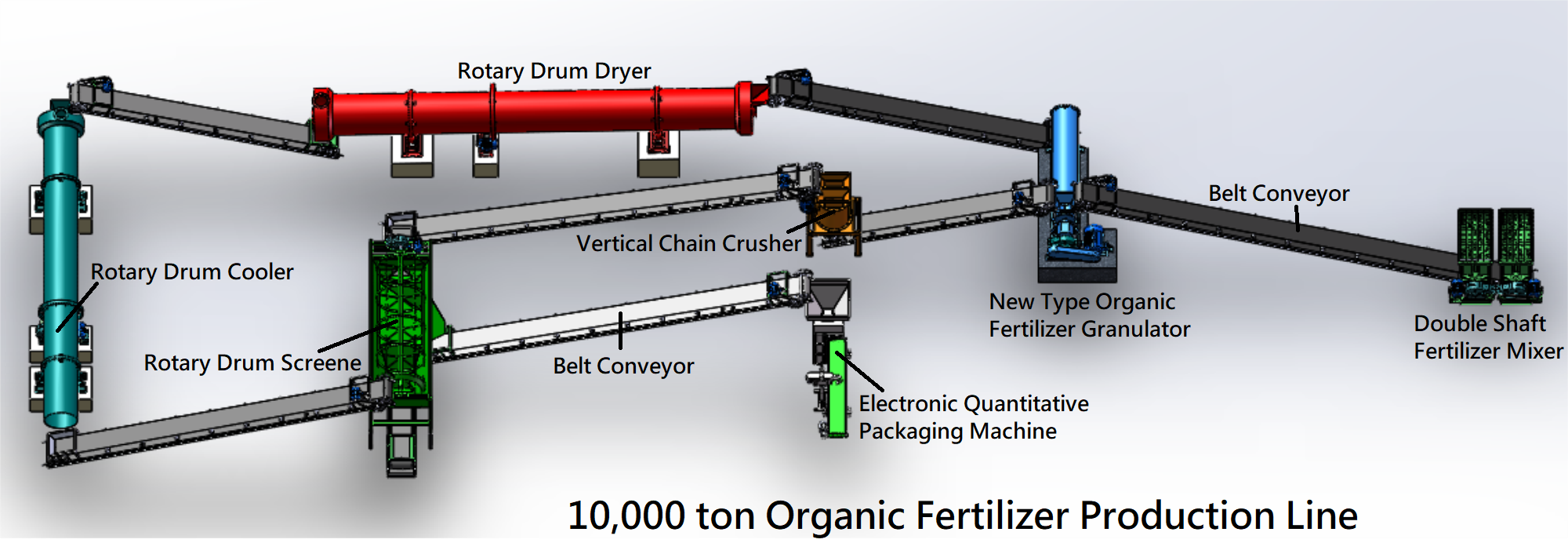

Naqshadeynta iyo soo saarista khadka wax soo saarka bacriminta organic oo dhan.Qalabka khadka wax soo saarka inta badan waxaa ka mid ah isku-darka laba-dhidib ah, granulator cusub oo bacriminta organic, qalajiyaha rullaluistemadka, qaboojiyaha rullaluistemadka, mashiinka shaandheeyo rullaluistemadka, burburin silsilad toosan, conveyor suunka, mashiinka baakadaha si toos ah iyo qalab kale oo caawimo ah.

Bacriminta dabiiciga ah waxaa laga samayn karaa hadhaaga methane, qashinka beeraha, xoolaha iyo digada digaaga iyo qashinka degmada.Qashinkan dabiiciga ah wuxuu u baahan yahay in si dheeraad ah loo sii farsameeyo ka hor inta aan loo beddelin bacrimiyeyaasha dabiiciga ah ee ganacsiga ee qiimaha ganacsi ee iibka ah.Maalgelinta lagu beddelayo qashinka qashinku waa mid aad u qiimo badan.

Khadka wax soo saarka bacriminta dabiiciga ah wuxuu ku habboon yahay:

-- Soo saarista saxarada lo'da bacriminta dabiiciga ah

-- Soo saarista saxarada lo'da bacriminta dabiiciga ah

-- Soo saarista digada doofaarka bacriminta dabiiciga ah

-- Soo saarista digaaga iyo digada shinbiraha bacriminta dabiiciga ah

-- digada idaha wax soo saarka bacriminta organic

-- Bacriminta dabiiciga ah ka dib daaweynta qashinka bullaacadaha ee degmada

1. Waxaa loo isticmaalaa hawlaha halsano iyo ka saarista biyaha ee dhirta bacriminta organic, dhirta bacriminta isku dhafan, warshadaha wasakhda wasakhda, beeraha beerta iyo beero likaha.

2. Ku haboon halsano aerobic, waxaa loo isticmaali karaa iyada oo lala kaashanayo qolalka halsano qoraxda, taangiyada halsano iyo shifters.

3. Alaabooyinka laga helay halsano hawada sare ee heerkulka sare waxaa loo isticmaali karaa hagaajinta carrada, cagaarka beerta, daboolka qashinka, iwm.

Qodobbada muhiimka ah ee xakameynaya qaan-gaarnimada compost

1. Nidaaminta saamiga kaarboon-nitrogen (C/N)

C/N ku habboon ee u kala googo'da walxaha organic by noolaha guud waa qiyaastii 25:1.

2. xakamaynta biyaha

Sifeynta biyaha ee compost ee wax soo saarka dhabta ah waxaa guud ahaan lagu xakameynayaa 50% ~ 65%.

3. Kontoroolka hawo-qaadista ee Compost

Ogsajiinta hawada la sii daayo ayaa ah arrin muhiim u ah guusha compost.Waxaa guud ahaan la rumeysan yahay in oksijiinta ku jirta tuubada ay ku habboon tahay 8% ~ 18%.

4. Xakamaynta heerkulka

Heerkulka ayaa ah arrin muhiim ah oo saameynaysa habsami u socodka noolaha yaryar ee compost.Heerkulka halsano ee compost heerkulkiisu sarreeyo waa 50-65 darajo C, taasoo ah habka ugu badan ee la isticmaalo hadda.

5. xakamaynta salinity acid (PH).

PH waa arrin muhiim ah oo saameeya korriinka noolaha.PH ee isku dhafka compost waa inuu noqdaa 6-9.

6. Xakamaynta urta

Waqtigan xaadirka ah, microorganisms badan ayaa loo isticmaalaa si loo carfiyo.

1, Digada xoolaha: digada digaaga, digada doofaarka, digada idaha, digada lo'da, digada fardaha, digada bakaylaha, iwm.

2. Qashinka warshadaha: canabka, caleenta khalka, haraaga cassava, haraaga sonkorta, qashinka bayogaaska, haraaga dhogorta, iwm.

3. Qashinka beeraha: caws dalagga, bur soybean, budada cudbi, iwm.

4. Qashinka guriga: qashinka jikada

5. Qulqulka: dhoobada magaalada, dhoobada webiga, dhoobada shaandhada, iwm.

Habka wax-soo-saarka aasaasiga ah ee bacriminta organic waxaa ka mid ah: shiida alaabta ceeriin → halsano → isku darka maaddooyinka (isku darka walxaha kale ee organic-inorganic, NPK≥4%, walxaha organic ≥30%) → granulation → baakadaha.Fiiro gaar ah: khadkan wax soo saarku waa tixraac kaliya.

Ma bixin karno oo kaliya nidaamka wax soo saarka bacriminta organic dhamaystiran, laakiin sidoo kale waxay bixiyaan hal qalab ee habka waafaqsan baahida dhabta ah.

1. Khadka wax soo saarka ee bacriminta dabiiciga ah wuxuu qaataa tignoolajiyada wax soo saarka ee horumarsan, kaas oo dhamaystiri kara wax soo saarka bacriminta organic markiiba.

2. Qaado granulator gaar ah oo cusub oo bacriminta organic, leh heerka granulation sare iyo xoogga qayb sare.

3. Alaabada ceeriin ee laga soo saaro bacriminta organic waxay noqon kartaa qashinka beeraha, xoolaha iyo digada digaaga iyo qashinka gudaha ee magaalooyinka, alaabta ceeriin ah ayaa si ballaaran loo qabsan karaa.

4. Waxqabadka xasilloon, caabbinta daxalka, xirashada caabbinta, isticmaalka tamarta yar, nolosha adeegga dheer, dayactirka habboon iyo hawlgalka, iwm.

5. Waxtarka sare, faa'iidooyinka dhaqaale ee wanaagsan, wax yar iyo regranulator.

6. Qaabeynta khadka wax soo saarka iyo wax soo saarka ayaa lagu hagaajin karaa iyadoo loo eegayo shuruudaha macaamiisha.

Qalabka wax-soo-saarka bacriminta dabiiciga ah waxaa ka mid ah qalabka halsano, laba-dhidib-ku-darka, mashiinka cusub ee bacriminta organic, qalajiyaha qalajiyaha, qaboojiyaha durbaanka, mashiinka baaritaanka durbaanka, silo, mashiinka baakadaha otomaatiga ah, burburin silsilad toosan, gudbiyaha suunka, iwm.

Habka wax soo saarka bacriminta dabiiciga ah:

1) habka halsano

Qashin-qubka nooca abaartu waa qalabka halsano ee ugu isticmaalka badan.Xirmooyinka jeexan waxa ay ka kooban yihiin haan halsano ah, jidka socodka, nidaamka korontada, qalabka barokaca iyo nidaamka badan ee badan.Qaybta rogrogmi karta waxaa wata rollers horumarsan.Flipper Hydraulic wuxuu kici karaa oo u dhici karaa si xor ah.

2) habka granulation

Nooc cusub oo ah granulator bacriminta organic ayaa si weyn loogu isticmaalaa granulation bacriminta organic.Waa granulator gaar ah oo loogu talagalay alaabta ceeriin sida saxarada xoolaha, midhaha qudhuntay, qolofta, khudaarta ceeriin, bacriminta cagaaran, bacriminta badda, bacriminta beeraha, saddex qashinka, noolaha iyo walxaha kale ee qashinka dabiiciga ah.Waxay leedahay faa'iidooyinka heerka sare ee granulation, hawlgalka xasilloon, qalab raagaya iyo nolosha adeeg dheer, waana doorasho ku habboon soo saarista bacriminta organic.Guryaha mashiinkani wuxuu qaataa tuubo aan fiicneyn, kaas oo aad u adkeysanaya oo aan qalloocin.Marka lagu daro naqshadeynta deked-badbaadada, shaqada mishiinku waa mid deggan.Xoogga cufan ee granulator-ka cusub ee bacriminta dabiiciga ah ayaa ka sarreeya kan granulators diskka iyo granulators durbaanka.Cabbirka walxaha waxaa lagu hagaajin karaa iyadoo loo eegayo shuruudaha macaamiisha.Granulator-ku wuxuu aad ugu habboon yahay granulation tooska ah ee qashinka dabiiciga ah ka dib halsano, badbaadinta habka qalajinta oo si weyn u yareynaya kharashka wax soo saarka.

3) habka qalajinta iyo qaboojinta

Qoyaanka qoyaanka ka dib granulation by granulator waa sarreeyaa, sidaas darteed waxay u baahan tahay in la qalajiyo si loo buuxiyo heerka heerka biyaha.Qalajiyaha waxaa inta badan loo isticmaalaa in lagu qalajiyo qaybo leh qoyaan gaar ah iyo cabbirka walxaha soo saarista bacriminta isku jira bacriminta.Heerkulka walxaha qalajinta ka dib waa mid aad u sarreeya, waana in la qaboojiyaa si looga hortago bacriminta inay ku ururto.Qaboojiyaha waxaa loo isticmaalaa qaybaha qaboojinta ka dib marka la qalajiyo waxaana lagu daraa qalajiyaha rotary, taas oo si weyn u wanaajin karta waxtarka qaboojinta, yaraynta xoogga shaqada, kordhinta dhalidda, sii dheeraysa qoyaanka qaybaha iyo yaraynta heerkulka bacriminta.

4) habka baaritaanka

Wax soo saarka, si loo hubiyo in la mid ah alaabta la dhammeeyey, qaybaha waa in la baaro ka hor baakadaha.Mashiinka shaandhaynta rullaluistu waa qalabka shaandheynta caadiga ah ee habka wax soo saarka ee bacriminta isku dhafan iyo bacriminta organic.Waxaa loo isticmaalaa in lagu kala saaro alaabooyinka la dhammeeyey iyo isku-darka aan ku habboonayn iyo in la sii gaarsiiyo kala-soocidda alaabta la dhammeeyey.

5) habka baakadaha

Ka dib marka mishiinka baakadaha la shaqaysiiyo, quudiyaha cufisjiidadu waxa uu bilaabayaa in uu shaqeeyo, waxa uu ku shubaa shayga fuudka miisaanka, oo waxa uu dhex galinayaa bac dhexda hopper-ka miisaanka.Marka uu miisaanku gaadho qiimaha caadiga ah, quudiyaha cufjiidadka ayaa joojinaya socodsiinta.Hawlwadeenku waxa uu qaadayaa alaabta baakadaysan ama waxa uu bacda baakadka saarayaa qaadiyaha suunka mishiinka tolida.