Soo saaraha qalabka bacriminta dabiiciga ah.

Yizheng Heavy Industry waa soo saaraha xirfadeed eeqalabka bacriminta organic.Alaabtayadu waxay leeyihiin tilmaamo dhamaystiran iyo tayo wanaagsan!Alaabooyinka si fiican ayaa loo sameeyay waxaana lagu keenaa waqtiga.Ku soo dhawoow inaad wacdo oo aad iibsato.

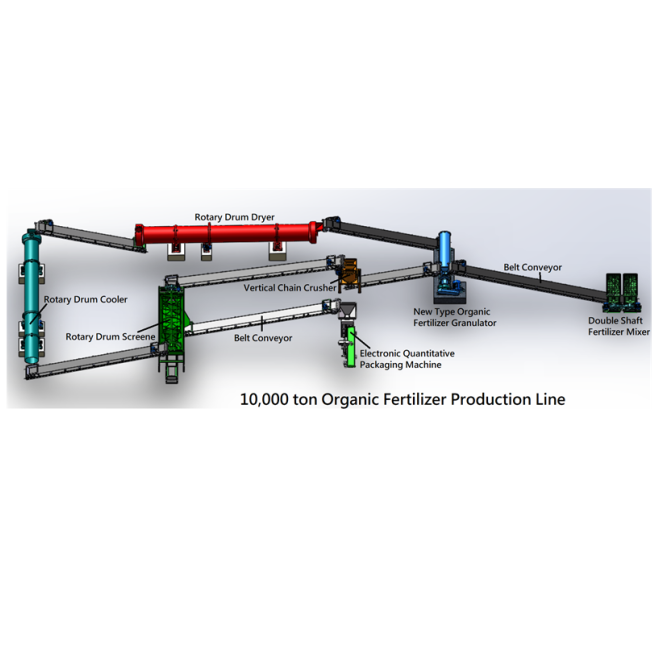

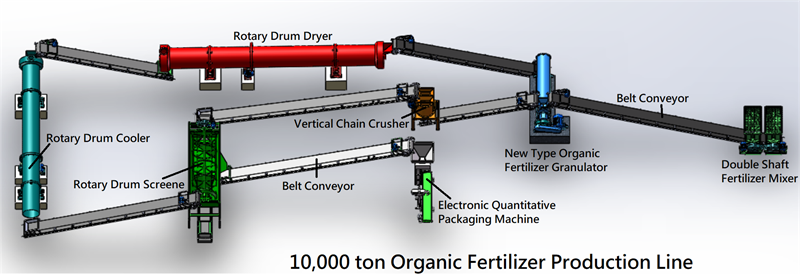

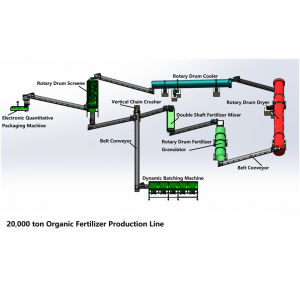

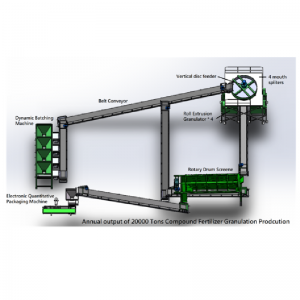

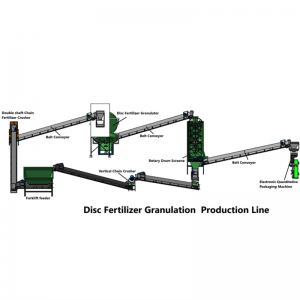

Ourline soo saarka bacriminta organic dhamaystiranQalabka inta badan waxaa ka mid ah qase labajibbaaran, granulator bacriminta organic, durbaan qalajiyaha, qaboojiyaha durbaanka, mishiinka baarista durbaanka, burburiyaha silsiladda toosan, qaade suunka, mashiinka baakadaha tooska ah iyo qalab kale oo caawiya.

Qalabka ceeriin eebacriminta organicwaxay noqon kartaa hadhaaga methane, qashinka beeraha, xoolaha iyo digada digaaga iyo qashinka gudaha magaalada.Qashinkan organic waxay u baahan yihiin in si dheeraad ah loo sii farsameeyo ka hor inta aan loo beddelin bacrimiyeyaasha organic-ga ah ee ganacsiga leh qiimaha iibka.Maalgelinta lagu beddelayo qashinka hanti iyo "qashinka u beddelaya hanti" gabi ahaanba waa mid mudan.

socodka habka wax soo saarka:

1. Habka halsano:

Lane turner waa qalabka rogista halsano ee ugu isticmaalka badan.Werweriyaha dabaysha compost waxa ka mid ah jeexdin halsano, jidka socodka, nidaamka korontada, qaybaha leexinta iyo nidaamka taangiyada badan.Halsano iyo qaybaha leexinta waxay qaataan rullaluistemadka horumarsan.Qalabka halsano ee leexiyaha bacriminta haydarooliga waa la kicin karaa oo si xor ah loo dejin karaa.

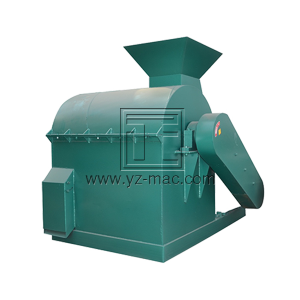

2. Habka granulation

Mashiinka granulation bacriminta cusub ee bacriminta organic waxaa si weyn loogu isticmaalaa granulation bacriminta organic, waana bacriminta loogu talagalay pellet granulation bacriminta si ay u granulated qashinka organic, sida digada xoolaha, khudaar qudhuntay, midho diiray, khudaarta ceeriin, digada cagaaran, digada badda, digada beeraha, saddex Qashinka iyo noolaha iwm Sababo la xiriira heerka granulation sare, hawlgalka deggan, qalab raagaya iyo nolosha adeeg dheer, waxa ay ahayd doorashada ugu fiican ee wax soo saarka bacriminta organic.Qolfoofka warshadda bacriminta pellet-ka waxa ay ka samaysan yihiin tuubo aan tol lahayn, waara oo aan weligood qalloocin.Marka lagu daro nakhshad saldhig oo sugan, taasoo ka dhigaysa mashiinkani inuu si xasiloon u shaqeeyo.Xoogga cufan ee nooca cusub ee granulator-ka ayaa ka sarreeya granulator-ka disc iyo granulator durbaanka rotary.Cabbirka walxaha waa la hagaajin karaa si waafaqsan shuruudaha macaamiisha.Bacriminta bacriminta Tani waxay aad ugu habboon tahay-granulation-ka tooska ah ka dib halsano organics, badbaadinta habka qalajinta, iyo si weyn u yareynaya kharashka wax soo saarka.

3. Habka qalajinta iyo qaboojinta bacriminta

Bacriminta granular ee ay samaysay granulator bacriminta ayaa leh qoyaan badan waana in la qalajiyo si loo buuxiyo heerka.Mashiinka qalajinta durbaanka rotary waxaa inta badan loo isticmaalaa in lagu qalajiyo bacriminta leh huurka gaar ah iyo cabbirka qayb ka mid ah bacriminta isku dhafka ah iyo wax soo saarka bacriminta organic.Bacriminta qalajinta ka dib waxay leedahay heerkul sare waana in la qaboojiyo si looga hortago bacriminta.Mashiinka qaboojinta durbaanka Rotary waxaa loo isticmaalaa in lagu qaboojiyo bacriminta leh heerkul gaar ah iyo cabbirka walxaha ee khadka wax soo saarka bacriminta iyo khadka soosaarka bacriminta organic.Qaboojiyaha waxaa loo isticmaalaa in lagu daro qalajiyaha wareega, kaas oo si weyn u kordhin kara heerka qaboojinta, hoos u dhigi kara xoogga shaqada, kordhinta awoodda, oo dheeraad ah ka saar qoyaanka iyo yaraynta heerkulka bacriminta.

4. Habka Baarista Bacriminta

Soosaarka bacriminta, bacriminta granular bacriminta waa in la baaro ka hor baakadaha si loo hubiyo isku mid ahaanshaha alaabta la dhammeeyay.Mashiinka baarista durbaanka Rotary waa qalab caadi ah oo loo isticmaalo warshadaha bacriminta wax soo saarka bacriminta isku dhafan iyo wax soo saarka bacriminta organic.Shaashadda Rotary waxaa inta badan lagu isticmaalaa khadka soo saarista bacriminta si loo kala saaro alaabta dhammaatay iyo alaabta soo laabanaysa.Trommel-ka waxa kale oo loo isticmaali karaa in lagu kala saaro alaabta la dhammeeyey.

5. Bacriminta Bacriminta

Alaabta waxaa lagu quudiyaa quudiyaha nooca cuf-jiidadka, ka dibna u geli habka miisaanka si isku mid ah iyada oo loo marayo quudiyaha nooca cuf-jiidadka ee ka imanaya qashinka kaydka ama khadka wax soo saarka.Qudeeyaha nooca culeyska culeyska ayaa bilaaba inuu ordo ka dib marka uu shido mashiinka wax lagu xiro.Kadibna alaabta waxaa lagu buuxin doonaa boodboodka miisaanka, iyada oo loo marayo boodboodka miisaanka oo laga buuxiyey bac.Marka uu miisaanku gaadho qiimihii hore loo dejiyay, quudiyaha nooca cufjiidadu wuu joojin doonaa socodsiinta.Hawl-wadeenadu waxa ay kaxeeyaan bacda la buuxiyey, ama waxay dul dhigaan suunka qaadaha mashiinka tolista.Habka xirxiradu wuu dhammaanayaa.

Si aad u hesho xalal faahfaahsan ama alaab, fadlan fiiro gaar ah u yeelo website-kayaga rasmiga ah:

https://www.yz-mac.com/introduction-of-organic-fertilizer-production-lines/