Waxaan khibrad buuxda u leenahay khadka wax-soo-saarka granulation extrusion-ka ee aan qalalan.Ma ahan oo kaliya diiradda saaraya xiriir kasta oo geeddi-socodka wax soo saarka, laakiin sidoo kale had iyo jeer haleelaan faahfaahinta habka ee khad kasta oo wax soo saarka oo dhan si habsami leh u gaarno isku-xirnaanta.Habka wax soo saarka oo dhammaystiran waa mid ka mid ah faa'iidooyinka ugu muhiimsan ee iskaashigaaga Yizheng Heavy Industries.Waxaan bixinaa xalalka wax soo saarka ee habaysan iyadoo loo eegayo baahida dhabta ah ee macaamiisha.

No line wax soo saarka granulation extrusion qalajiyey soo saari kartaa sare, dhexdhexaad ah iyo bacriminta xarunta hoose ee dalagyada kala duwan.Khadka wax-soo-saarka uma baahna inuu noqdo mid qallalan, oo leh maalgashi yar iyo isticmaalka tamarta yar.

rullaluistemadka oo aan engegin granulation extruding waxaa loo qaabayn karaa qaybo ka mid ah qaabab iyo cabbiro kala duwan oo la extruded karaa in ay soo saaraan qiyaaso kala duwan.

Bacriminta isku dhafan waxay leedahay sifooyinka granulation lebbiska, midabka dhalaalaya, tayada deggan, iyo kala diri fudud oo lagu nuugo dalagyada.Gaar ahaan, waa mid ilaa xad badbaado u ah iniinaha si ay u koraan bacriminta.Ku habboon dhammaan noocyada ciidda iyo sarreenka, galleyda, qaraha iyo miraha, lawska, khudaarta, digirta, ubaxa, geedaha miraha iyo dalagyada kale.Waxay ku habboon tahay bacriminta saldhigga, bacriminta, bacriminta bacriminta, bacriminta iyo waraabka.

Qalabka ceeriin ee wax soo saarka bacriminta isku dhafan waxaa ka mid ah HOL, ammonium chloride, ammonium sulfate, dareeraha ammonia, ammonium monophosphate, diammonium phosphate, chloride potassium, potassium sulfate, oo ay ku jiraan qaar dhoobo ah iyo kuwa kale.Qalab dabiici ah oo kala duwan ayaa lagu daraa iyadoo loo eegayo baahida ciidda:

1. Xaarka Xoolaha: Digaagga, Saxarada Doofaarka, Saxarada Idaha, Heesta Lo'da, Digada Fardaha, Digada Bakaylaha, iwm.

2. Qashinka warshadaha: canabka, caleenta khalka, haraaga cassava, haraaga sonkorta, qashinka bayogaaska, haraaga dhogorta, iwm.

3. Qashinka beeraha: caws dalagga, bur soybean, budada cudbi, iwm.

4. Qashinka guriga: qashinka jikada

5. Qulqulka: dhoobada magaalada, dhoobada webiga, dhoobada shaandhada, iwm.

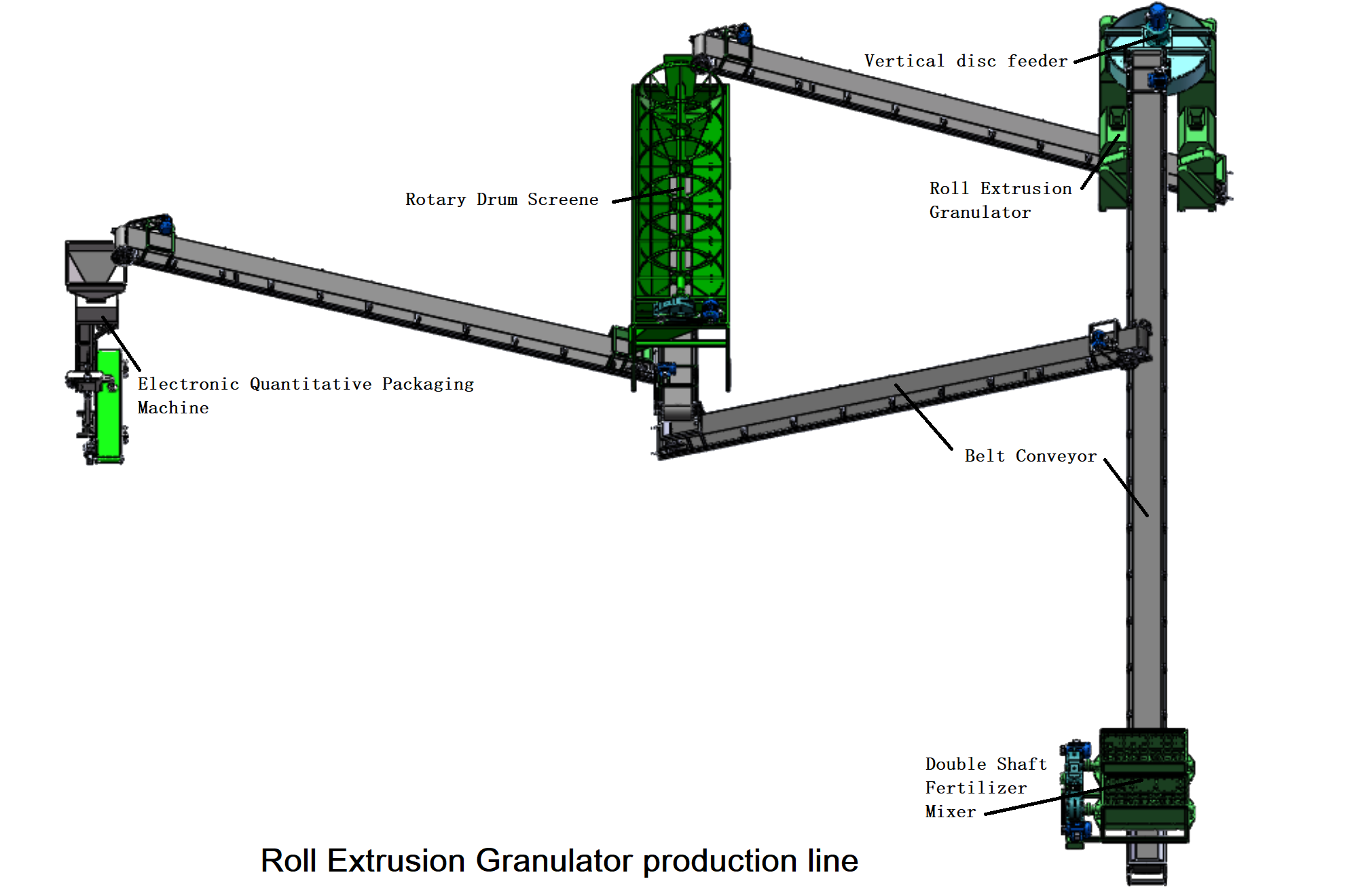

Waxaanu bixinaa khadadka wax-soo-saarka granulation extrusion-ka oo dhamaystiran oo aan u baahnayn in la qalajiyo.Qalabka khadka wax soo saarka inta badan waxaa ka mid ah isku-darka, feedhiyaha diskka, mashiinka granulation rullaluistemadka, mashiinka shaandhada rullaluistemadka, qaadaha suunka, mashiinka baakadaha otomatiga ah iyo qalab kale oo caawiya.

Sida soo saaraha xirfadeed ee qalabka wax soo saarka bacriminta, waxaan siinaa macaamiisha qalabka wax soo saarka iyo xalka ugu habboon ee baahida awoodda wax soo saarka ee kala duwan sida 10,000 tan sannadkii ilaa 200,000 tan sannadkii.

1. Qalabaynta cadaadiska makaanikada waxaa la isticmaalaa iyada oo aan la kululayn ama la huurin alaabta ceeriin.

2. Ku habboon alaabta ceeriin ee kuleylka xasaasiga ah, sida ammonium bicarbonate

3. Looma baahna in la qalajiyo habka, iyada oo maalgelin yar iyo isticmaalka tamarta yar.

4. Biyo wasakh ah oo aan lahayn, gaaska sii daaya, deegaanka oo aan wasakhayn.

5. Qaybinta xajmi-qaybintu waa lebis, mana jirto kala-soocid iyo is-daba-marin.

6. Qaabaynta is haysta, tignoolajiyada horumarsan, hawlgal xasiloon iyo dayactir ku habboon.

7. fududahay in la shaqeeyo, fududahay in la xaqiijiyo xakamaynta tooska ah, iyo hagaajinta waxtarka wax soo saarka.

8. Waxaa jira codsiyo kala duwan oo alaab cayriin ah oo aan lahayn shuruudo waxqabad gaar ah.

Ma jiro khadka wax soo saarka qalajinta extrusion extrusion oo ay ku jiraan basbas toos ah, gudbiyaha suunka, blender double-axis, feeder disc, mishiinka granulation extrusion, mashiinka baaritaanka rullaluistemadka, bakhaar dhammeeyey, mashiinka baakadaha si toos ah, iwm.

1. Mashiinka Batching Dynamic

Mashiinka maaddooyinka tooska ah waxay quudiyaan alaabta ceeriin iyadoo loo eegayo saamiga caanaha, kaas oo si toos ah u dhammaystiri kara habka wax-soo-saarka ee saxnaanta sare iyo waxtarka, si loo hubiyo tayada bacriminta.Ka dib maaddooyinka, walxaha waxaa loo raray blender-ka labajibbaaran.

2. Isku-dhafka Bacriminta Shaft Double

Isku-darka saxanku wuxuu isticmaalaa yareeyaha cirbadda cycloid si uu u wado dunta, ka dibna u wado cududda wax kicinaysa si uu u wareego oo u walaaqo.Iyada oo si joogto ah loo rogo iyo walaaqida garbaha cududda isku dhafka ah, alaabta ceeriin ayaa si buuxda isugu qasan.Walxaha isku dhafan ayaa laga soo saaraa meesha hoose.Saxanku wuxuu qaataa saxan polypropylene ama dahaarka birta ah, taas oo aan fududayn in lagu dhejiyo oo fudud oo la taaban karo.

3. Duub-baxa Granulator Extrusion

Walxaha cayriin ee isku qasan waxa laga soo qaadaa suunka oo la geeyaa feedhaha, kaas oo si siman u soo diraya shayga afarta rullaluley ee ka hooseeya quudiyaha iyada oo loo sii marayo hopper.Mashiinku waxa uu u tuujiyaa walxaha googo'a qolka jabay ee rullalulatu hoostiisa iyada oo loo marayo rolleer-socod sare oo korantada ah, ka dibna kala sooca qaybaha loo baahan yahay marka uu ul laba-dhidib ah usha yey-gaaban uu wareego.Roller-ku wuxuu ka samaysan yahay walxo cusub oo u adkaysta daxalka, xidhashada iyo wax u adkaysta

4. Baadhitaanka Durbaanka Rotary

Qaybaha granulation extified waxaa lagu qaadaa filtarka rullaluistemadka iyada oo loo marayo conveyor suunka, iyo qayb aan tayo lahayn ayaa ka soo qulqulaya outlet qaybo waaweyn ee dhinaca dhex dalool shaashadda, ka dibna loo qaado disc feeder for granulation sare, iyo qaybo u qalma waxaa lagu quudin ka meesha hoose ee laga soo baxo oo loo qaado meesha la dhammeeyey.

5. Mashiinka Baakaynta Tirade Elektarooniga ah

Iyada oo loo marayo hopper-ka, walxaha tayada leh ayaa lagu miisaamay tiro ahaan, ka dibna waxaa lagu baakadeeyaa mashiinka baakadaha oo toos ah.