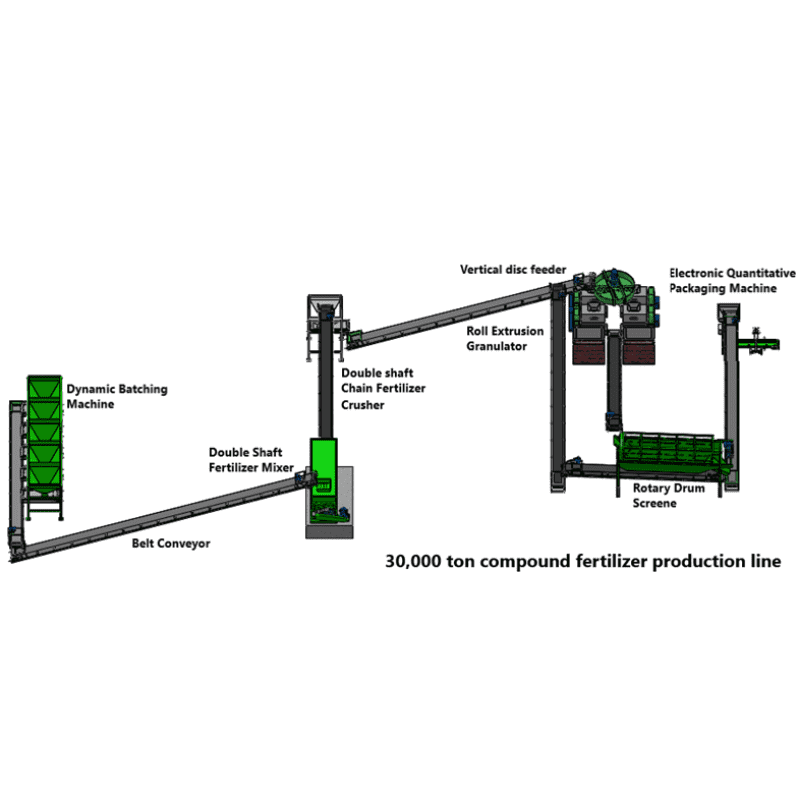

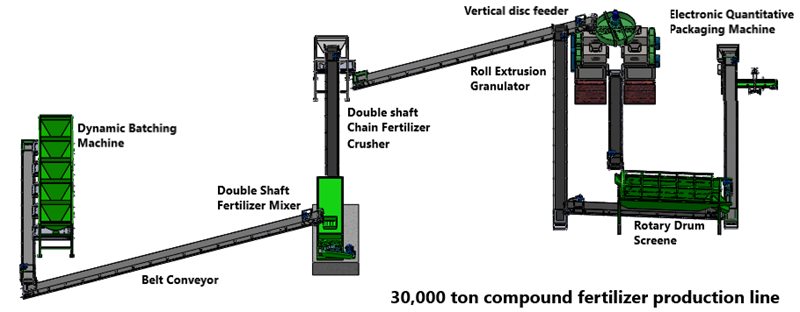

No qalajinta extrusion ka kooban bacriminta line soo saarka.

Khadka wax soo saarka granulation extrusion aan qalajinwaxay soo saari kartaa bacrimiyeyaasha isku-dhafka sare, dhexe iyo hoose ee dalagyada kala duwan.Khadka wax soo saarka uma baahna qalajin, wuxuu leeyahay maalgashi hooseeya iyo isticmaalka tamarta yar.Rollers-ka cadaadiska ee granulation extrusion-ka aan qallajin waxaa loo qaabeyn karaa qaabab iyo qiyaaso kala duwan si ay u soo saaraan granules cabbirro iyo qaabab kala duwan.

No qalajinta extrusion ka kooban bacriminta line soo saarkawaxaa hagaajiyay Yizheng Heavy Industries, shirkad ku takhasustay cilmi-baarista, horumarinta, wax soo saarka iyo iibinta qalabka wax soo saarka bacriminta organic.Bixi qalab farsamaynta bacriminta oo dhamaystiran, rakibid iyo hawlgelin bilaash ah, tababar bilaash ah, iyo adeegyo dayactir.

Granulator-ka qallayl-la'aanta ah ee qallalan waxaa ka mid ah maaddooyin toos ah, mashiinnada suunka, qasiyeyaasha biaxial, feederiyeyaasha saxanka, mashiinnada granulation extrusion, shaandhada rullaluistuyada, bakhaarrada la dhammeeyey, mashiinnada baakadaha tooska ah, iwm.

1. Mashiinka Batching Dynamic

Mashiinka maaddooyinka tooska ah waxay quudiyaan alaabta ceeriin iyadoo loo eegayo saamiga caanaha, kaas oo si toos ah u dhammaystiri kara habka wax-soo-saarka ee saxnaanta sare iyo waxtarka, si loo hubiyo tayada bacriminta.Ka dib maaddooyinka, walxaha waxaa loo raray blender-ka labajibbaaran.

2. Isku-dhafka Bacriminta Shaft Double

Isku-darka saxanku wuxuu isticmaalaa yareeyaha cirbadda cycloid si uu u wado dunta, ka dibna u wado cududda wax kicinaysa si uu u wareego oo u walaaqo.Iyada oo si joogto ah loo rogo iyo walaaqida garbaha cududda isku dhafka ah, alaabta ceeriin ayaa si buuxda isugu qasan.Walxaha isku dhafan ayaa laga soo saaraa meesha hoose.Saxanku wuxuu qaataa saxan polypropylene ama dahaarka birta ah, taas oo aan fududayn in lagu dhejiyo oo fudud oo la taaban karo.

3. Roller extrusion granulator

Walxaha cayriin ee isku qasan waxa laga soo qaadaa suunka oo la geeyaa feedhaha, kaas oo si siman u soo diraya shayga afarta rullaluley ee ka hooseeya quudiyaha iyada oo loo sii marayo hopper.Mashiinku waxa uu u tuujiyaa walxaha googo'a qolka jabay ee rullalulatu hoostiisa iyada oo loo marayo rolleer-socod sare oo korantada ah, ka dibna kala sooca qaybaha loo baahan yahay marka uu ul laba-dhidib ah usha yey-gaaban uu wareego.Roller-ku wuxuu ka samaysan yahay walxo cusub oo u adkaysta daxalka, xidhashada iyo wax u adkaysta

4. Baadhitaanka Durbaanka Rotary

Qaybaha granulation extified waxaa lagu qaadaa filtarka rullaluistemadka iyada oo loo marayo conveyor suunka, iyo qayb aan tayo lahayn ayaa ka soo qulqulaya outlet qaybo waaweyn ee dhinaca dhex dalool shaashadda, ka dibna loo qaado disc feeder for granulation sare, iyo qaybo u qalma waxaa lagu quudin ka meesha hoose ee laga soo baxo oo loo qaado meesha la dhammeeyey.

5. Baakaynta Tirada Elektarooniga ah

Iyada oo loo marayo hopper-ka, walxaha tayada leh ayaa lagu miisaamay tiro ahaan, ka dibna waxaa lagu baakadeeyaa mashiinka baakadaha oo toos ah.

Si aad u hesho xalal faahfaahsan ama alaab, fadlan fiiro gaar ah u yeelo website-kayaga rasmiga ah:

https://www.yz-mac.com/npk-compound-fertilizer-extrusion-granulation-production-line/