Nooc Cusub oo Bacriminta dabiiciga ah Granulator

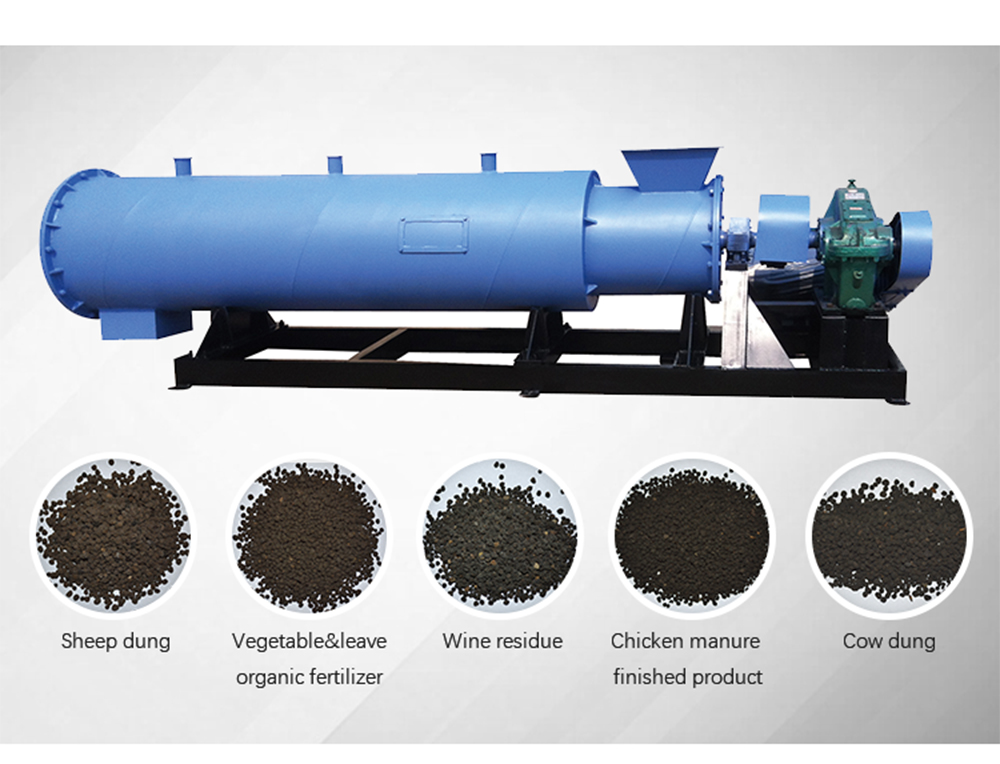

Nooc Cusub oo Bacriminta dabiiciga ah Granulatorwaxaa si weyn loo isticmaalaa in granulation ee bacriminta organic.Nooc cusub oo ah granulator bacriminta dabiiciga ah, oo sidoo kale loo yaqaan mashiinka qoyan ee kicinta qoyan iyo mashiinka kicinta kicinta gudaha, waa granulator cusub oo bacriminta dabiiciga ah oo ay soo saartay shirkadeena.Mashiinku kaliya kuma ekaan karo noocyo kala duwan oo walxo organic ah, gaar ahaan agabka fiber-ka ah ee adag ee ay adagtahay in lagu granulated qalabka caadiga ah, sida cawska dalagga, hadhaaga khamriga, hadhaaga likaha, hadhaaga daroogada, saxarada xoolaha iyo wixii la mid ah.granulation waxaa la samayn karaa ka dib halsano, iyo sidoo kale waxaa lagu gaari karaa saamaynta wanaagsan ee hadhuudh samaynta si aysiidhka iyo dhoobada degmada.

Bacriminta dabiiciga ah ee ganacsiga:

a) Qashinka warshadaha: sida firileyda, miraha khalka, haraaga cassava, hadhaaga sonkorta, haraaga furfuralka, iwm.

b) Walaxda degmada: sida dhoobada webiga, wasakhda bulaacada, iwm. Bacriminta dabiiciga ah wax soo saarka alaabta ceeriin iyo sahayda aasaasiga ah: ciidda xariirta, haraaga likaha, hadhaaga phosphocitric acid, haraaga cassava, dhoobada borotiinka, haraaga glucuronide, humic amino acid aashito, hadhaaga saliidda, dambaska cawska, budada qolofka, isla markaaba shaqaynaysa, budada qolofka lawska, iwm.

Bacriminta noolaha-Organic:

a) Qashinka beeraha: sida caws, soybean, cudbi, iwm.

b) Digada xoolaha iyo digaaga: sida digada digaaga, lo'da, idaha iyo digada fardaha, digada bakaylaha;

c) Qashinka guriga: sida qashinka jikada;

Thenooca cusub granulator bacriminta organicwaxay isticmaashaa xoogga kicinta farsamada ee wareegga xawaaraha sare iyo aerodynamics ka soo baxa si ay si joogto ah isugu daraan, granulation, spherical, cufan iyo hababka kale ee budada ganaaxa ee mashiinka, si loo gaaro granulation.Qaabka qurubku waa wareegsan yahay, cabbirka qaybuhu guud ahaan waa inta u dhaxaysa 1.5 iyo 4 mm, iyo cabbirka walxaha 2 ~ 4.5mm waa ≥90%.Dhexroorka walxaha ayaa si habboon loogu hagaajin karaa isku-dhafka walxaha iyo xawaaraha dunta.Caadiyan, inta hoose ee qadarka isku dhafka ah, ayaa sare u kaca xawaaraha wareega, qayb yar oo ka mid ah, iyo sii weynaada qaybta.

►Granule-ka alaabtu waa kubad wareegsan.

►Maadada organic waxay noqon kartaa mid sare ilaa 100%, samee granulate organic saafi ah.

►Qaybaha walxaha dabiiciga ah waxay ku kori karaan xoog gaar ah, looma baahna in lagu daro xiraha.marka granulating.

►Granule wax soo saarka waa cufan, waxay si toos ah u shaandheyn kartaa granulation ka dib si loo yareeyo tamarta.isticmaalka qalajinta.

►Halsano ka dib organics uma baahna inay engegaan, qoyaanka alaabta ceeriin waxay noqon kartaa 20% -40%.

Si loo daboolo baahiyaha bacriminta dabiiciga ah ee baaxadda weyn, WEZhengzhou Yizheng Heavy Machinery Co., Ltd.si xirfadaysan u qaabeeya oo u soo saara khadka soo saarista bacriminta organic iyo mashiinada ku habboon ee ku habboon agabka organic ee kala duwan, kaas oo ahaa hogaamiyaha berrinka Shiinaha.

| Wax-soo-saarka Sannadlaha ah ee Dhirta Bacriminta Dabiiciga ah ee Cabbirka Yar (300 Maalmood Shaqo) | |||||

| 10,000 oo tan/sanadkii | 20,000 oo tan/sanadkii | 30,000 oo tan/sanadkii | |||

| 1.4 tan / saac | 2.8 tan / saac | 4.2 tan / saac | |||

| Soosaarka Sannadlaha ah ee Dhirta Bacriminta Dabiiciga ah ee Dhexdhexaadka ah | |||||

| 50,000 oo tan/sanadkii | 60,000 oo tan/sanadkii | 70,000 oo tan/sanadkii | 80,000 oo tan/sanadkii | 90,000 oo tan/sanadkii | 100,000 oo tan/sanadkii |

| 6.9 tan/saacaddii | 8.3 tan / saac | 9.7 tan/saacaddii | 11 tan / saac | 12.5 tan / saac | 13.8 ton / saac |

| Wax-soo-saarka Sannadlaha ah ee Dhirta Bacriminta dabiiciga ah ee Weyn | |||||

| 150,000 oo tan/sanadkii | 200,000 oo tan/sanadkii | 250,000 oo tan/sanadkii | 300,000 oo tan/sanadkii | ||

| 20.8 tan / saac | 27.7 tan / saac | 34.7 tan / saac | 41.6 tan / saac | ||

Ka madax banaan xaddidaadyo xilliyeed iyo kharash yar oo ka sarreeya halsano Aerobic

"Qashinka u beddel khasnad", ma jirto daaweyn xun, daaweyn aan dhib lahayn

Swareegga wax soo saarka hort ee bacriminta organic

Shawlfulin iyo maamul ku habboon

- Habka halsano:

Halsano waa habka aasaasiga ah ee wax soo saarka.Qoyaanka, heerkulka iyo waqtiga ayaa u baahan in si adag loo xakameeyo.Gawaarida Compost waa mashiinka bacriminta organic ee loo isticmaalo in lagu dardargeliyo halsano ee noolaha yar yar iyo horumarinta tayada compost.

- Habka Burburinta:

Walxaha buro waa in la burburiyaa ka dib habka halsano.Way adag tahay in arrinta gacanta laga dhigo granules.Sidan, waa lagama maarmaan in la isticmaalo burburinta bacriminta.Waxaan kugula talineynaa macaamiisha inay doortaan qalabka qoyaanka sare leh mashiinka burburinta, maadaama ay burburin karto walxaha qoyan iyo waxtarka sare leh.

- Habka Granulating:

Waa habka wax soo saarka ee muhiimka ah ee dhammaan khadka wax soo saarka.Marka loo eego shuruudaha kala duwan, nafaqooyinka ayaa lagu dari karaa.Qaybaha wareegsan waa la farsameeyaa, taasoo badbaadinaysa tamar badan.Sidaa darteed, doorashada mashiinka bacriminta dabiiciga ah ee saxda ah ayaa si gaar ah muhiim u ah.Nooca cusub ee bacriminta organic granulator waa mashiinka ugu habboon.

- Habka qalajinta:

Ka dib markii granules, granules waxay u baahan yihiin qalajin.Qoyaanka bacriminta organic waa la dhimay ilaa 10% -40%.Mashiinka qallajinta durbaanka Rotary waa qalab lagu yareeyo qoyaanka qaybaha, taas oo suurtagal ah soo saarista bacriminta organic.

- Habka qaboojinta:

Si loo hubiyo tayada, qaybuhu waa inay qaboojiyaan ka dib marka la qalajiyo iyadoo la kaashanayo mashiinka qaboojinta durbaanka rotary.

- Habka Baaritaanka:

Waxaa jira bacrimiyeyaasha organic aan u qalmin inta lagu jiro wax soo saarka.Waxay u baahan tahay mashiinka baadhista bacriminta durbaanka rotary si loo kala saaro alaabta la diiday iyo walxaha caadiga ah.

- Habka xirxirida:

Mashiinka baakadaha bacriminta waxaa loo isticmaalaa bacriminta bacriminta warshadaysan.Waxaan u isticmaali karnaa mashiinka baakadaha si aan ugu xirno oo aan u bacdino qaybaha.Waxay ku guuleysan kartaa alaabta baakadka si toos ah oo hufan.

Moodooyinka qeexida granulator waa 400, 600, 800, 1000, 1200, 1500 iyo tilmaamo kale, kuwaas oo sidoo kale lagu habeyn karo iyadoo loo eegayo baahiyaha dhabta ah.

| Qaabka | Cabbirka Granule (mm) | Awood (kw) | Dareen (°) | Cabirka (L× W ×H) (mm)

|

| YZZLYJ-400 | 1 ~ 5 | 22 | 1.5 | 3500×1000×800 |

| YZZLYJ -600 | 1 ~ 5 | 37 | 1.5 | 4200×1600×1100 |

| YZZLYJ -800 | 1 ~ 5 | 55 | 1.5 | 4200×1800×1300 |

| YZZLYJ -1000 | 1 ~ 5 | 75 | 1.5 | 4600×2200×1600 |

| YZZLYJ -1200 | 1 ~ 5 | 90 | 1.5 | 4700×2300×1600 |

| YZZLYJ -1500 | 1 ~ 5 | 110 | 1.5 | 5400×2700×1900 |