Soo saaraha qalabka bacriminta organic Granular

Soo saaraha qalabka bacriminta organic Granular.

Yizheng Heavy Industry ee ugu weynkhadka wax soo saarka bacriminta organic, Qalabka Bacriminta dabiiciga ah oo dhamaystiran, waxa uu leeyahay saldhigga wax soo saarka qalabka oo dhan 80,000 oo mitir oo laba jibbaaran, wuxuu bixiyaa qalab dhammaystiran oo bacrimin ah, rakibid iyo hawlgelin bilaash ah, tababar bilaash ah, iyo adeegyo dayactir.

Doorashada alaabta ceeriin ee bacriminta organic iyo bacriminta bio-organic waxay noqon kartaa digada xoolaha kala duwan iyo qashinka organic.Qaabka wax soo saarka aasaasiga ah wuxuu ku kala duwan yahay noocyo kala duwan iyo alaabta ceeriin;alaabta ceeriin ee aasaasiga ah waa: digada digaaga, digada shinbiraha, digada goose, digada doofaarka , Lo'da iyo saxarada idaha, cawska dalagga, dhoobada filter warshadaha, bagaash, haraaga dabocase sonkorta, badarka distiller ee, haraaga daawada, haraaga furfural, haraaga fungus, bean keega, keega abuur suufka ah, keega la kufsaday, dhuxusha cawska, iwm.

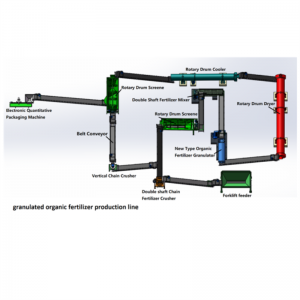

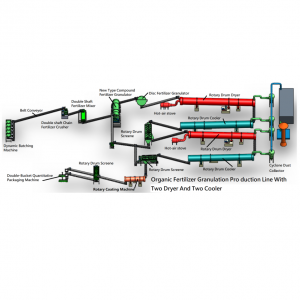

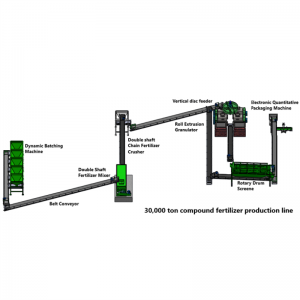

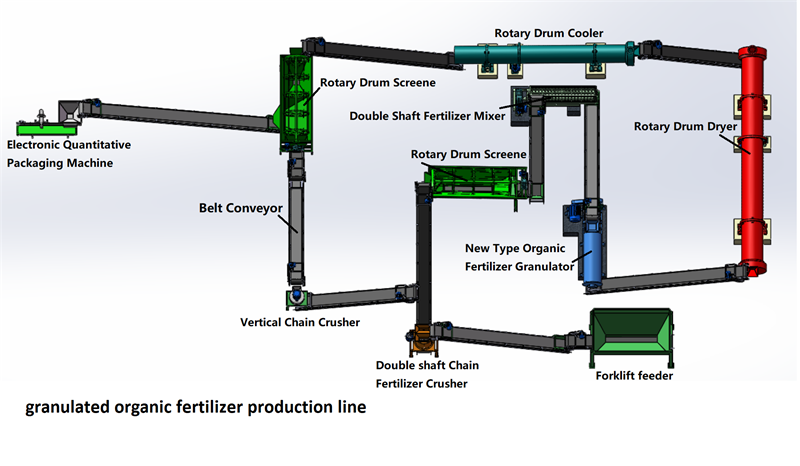

Habka wax soo saarka guud ee bacriminta organic waxaa ka mid ah halsano, isku dhafka, burburinta, granulation, qalajinta, qaboojinta, baaritaanka bacriminta, baakadaha, iwm.

Bacriminta dabiiciga ah ee Granular waxaa badanaa loo isticmaalaa si loo hagaajiyo ciidda oo loo bixiyo nafaqooyinka loo baahan yahay koritaanka dalagyada.Marka ay ciidda galaan, si dhakhso ah ayay u jajaban yihiin oo si dhakhso ah ayay u sii daayaan nafaqooyinka.Sababtoo ah bacriminta dabiiciga ah ee adag ayaa si tartiib tartiib ah u nuugaya, waxay ku sii jiraan waqti ka badan bacriminta organic budada ah.Isticmaalka bacriminta organic waxay si weyn u yaraynaysaa dhaawaca geedka laftiisa iyo waxyeelada deegaanka ciidda.

Mabda'a Shaqada:

1. Walaaq oo granullate

Inta lagu jiro habka wax walaaqda, compost budada ah ayaa lagu qasaa maaddooyinka ama caanaha la doonayo si loo kordhiyo qiimaha nafaqada.Ka dib isticmaal granulator bacriminta dabiiciga ah oo cusub si aad isku dhafka uga dhigto qaybo.Granulator bacriminta dabiiciga ah waxaa loo isticmaalaa in lagu sameeyo qaybo aan boodh lahayn oo cabbir iyo qaab la xakamayn karo.Granulator-ka cusub ee bacriminta dabiiciga ah wuxuu qaataa nidaam xiran, ma jiro dheecaan neef-mareen ah, iyo wax soo saar sare.

2. Qallaji oo qabow

Habka qalajinta ayaa ku habboon geed kasta oo soo saara alaab adag oo budada ah iyo granular.Qallajintu waxay yarayn kartaa qoyaanka ka soo baxa qaybaha bacriminta dabiiciga ah, waxay yaraynaysaa heerkulka kulaylka ilaa 30-40 ° C, iyo khadka soo saarista bacriminta dabiiciga ah ee granular waxay qaadanaysaa qalajiyaha iyo qaboojiyaha rullaluistemadka.

3. Baadhitaanka iyo baakaynta

Ka dib granulation, qaybaha bacriminta organic waa in la baaro si loo helo cabbirka qaybta loo baahan yahay lagana saaro qaybaha aan u hoggaansanayn xajmiga qaybta alaabta.Mashiinka shaandheynta rullaluistu waa qalabka shaandheynta caadiga ah, kaas oo inta badan loo isticmaalo kala soocidda alaabta dhammaatay iyo kala-saarista alaabta la dhammeeyey.Shaandheynta ka dib, cabbirka walxaha isku midka ah ee walxaha bacriminta organic waa la miisaamaa waxaana lagu baakadeeyaa mashiinka baakadaha tooska ah ee uu qaado suunka.

Si aad u hesho xalal faahfaahsan ama alaab, fadlan fiiro gaar ah u yeelo website-kayaga rasmiga ah:

https://www.yz-mac.com/powdered-organic-fertilizer-and-granulated-organic-fertilizer-production-lines/