Granulator qalalan

Qalalan qallalan, oo sidoo kale loo yaqaano mashiinka qallalan ee qalalan, waa qalab gaar ah oo loogu talagalay granulation ee alaabta qallalan iyada oo aan loo baahnayn dareeraha dareeraha ama dareeraha.Habkani waxa uu ku lug leeyahay isku-duubni iyo qaabaynta budo ama qaybo qallalan oo loo sameeyo granules, kuwaas oo sahlan in la xakameeyo, kaydiyo, iyo gaadiidka.Maqaalkan, waxaanu sahamin doonaa faa'iidooyinka, mabda'a shaqada, iyo codsiyada granulators qalalan ee warshadaha kala duwan.

Faa'iidooyinka Granulation Qalalan:

Ma jiraan wax-ku-xidhaha dareeraha ah ama xalinta: Qallajinta qallalan waxay meesha ka saartaa baahida dareeraha dareeraha ah ama dareeraha sida caadiga ah loo isticmaalo hababka granulation qoyan.Tani waxay yaraynaysaa kakanaanta geeddi-socodka granulation, waxay fududaynaysaa maaraynta iyo nadiifinta, waxayna meesha ka saaraysaa halista wasakhowga ama welwelka deegaanka ee la xidhiidha xirmooyinka dareeraha ah.

Degenaansho La Hagaajiyay: Granules-ka qallalan waxay xoojiyeen xasilloonida marka loo eego budada ama qaybaha dabacsan.Dabeecadda isku dhafan ee granules waxay yareysaa kala-soocidda, waxay ka hortagtaa nuugista qoyaanka, waxayna kor u qaaddaa sifooyinka socodka.Xasiloonidani waxay hubisaa tayada badeecada oo joogto ah waxayna yaraynaysaa khatarta xaalufka inta lagu jiro kaydinta ama gaadiidka.

Kharashka Keydka: Gawaarida qallalan waxay bixisaa faa'iidooyin kharash ah iyadoo meesha laga saarayo baahida dareeraha isku xidha, hababka qalajinta, iyo qalabka la xidhiidha.Waxay yaraynaysaa isticmaalka tamarta, wakhtiga wax soo saarka, iyo shuruudaha dayactirka, taasoo keentay kaydinta kharashka soosaarayaasha.

Guryaha Granule ee la beddeli karo: Granule-ka qallalan wuxuu u oggolaanayaa in si sax ah loo xakameeyo guryaha granul-ka, sida cabbirka, qaabka, cufnaanta, iyo porosity-ga.Tani waxay awood u siinaysaa soosaarayaasha inay ku habboonaadaan granules-ka shuruudaha codsiga gaarka ah, hubinta waxqabadka ugu fiican iyo sifooyinka badeecada ee la doonayo.

Mabda'a Shaqada ee Granulators qalalan:

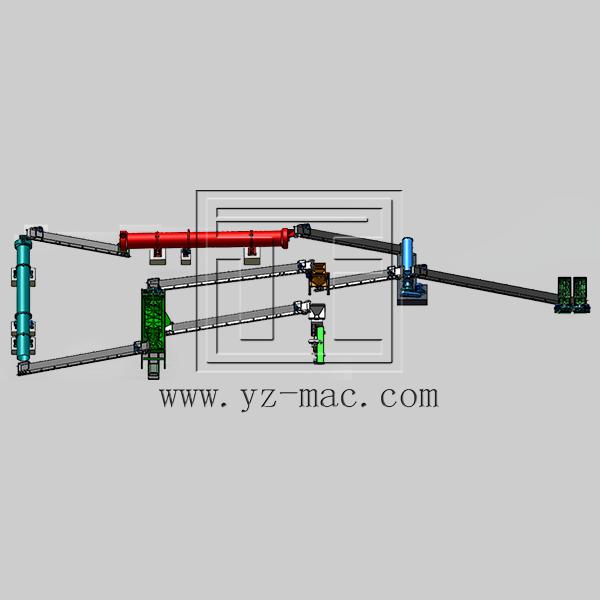

Granulators qallalan waxay caadi ahaan adeegsadaan laba hab oo waaweyn: cufnaanta iyo wax-shiidka.

Is-xakamaynta: Marxaladda is-burburinta, budada ama qaybo qallalan ayaa lagu quudiyaa qolka granulation, halkaas oo lammaane duubo-rogid-rogid ah ama saxaarad farsamaysan ay cadaadis saarto alaabta.Walxaha la isku cufiyey waxa ay maraan qallafsanaan balaastiig ah, samaynta ribbon ama go'.

Wax-shiidid: Xarig-jiifka ama xaashida ayaa markaa la dhex maraa habka wax-shiidka, kaas oo ka kooban mindiyo ama daabyo u kala jejebiya shayga cabbirka la rabo.Granules-ka la shiiday waa la ururiyaa waxaana la marsiin karaa tillaabooyin habaysan oo dheeraad ah, sida shaandhaynta ama dahaarka, haddii loo baahdo.

Codsiyada Granulators qalalan:

Warshadaha Daawooyinka: Granulation qalalan ayaa si weyn loogu isticmaalaa wax soo saarka dawada ee wax soo saarka ee kiniiniyada, kaabsoosha, iyo foomamka kale ee qiyaasta adag.Waxay awood u siinaysaa isku-buufinta tooska ah ee budada daroogada ee granules, hagaajinta socodka, labbiska, iyo tabletability.Granulators qallalan waxay ku habboon yihiin wax-soo-saarka dawooyinka yaryar iyo kuwa waaweyn labadaba.

Warshadaha Kiimikada: Qalalan qallalan ayaa laga shaqeeyaa warshadaha kiimikada si loo soo saaro bacrimiyeyaasha granular, kicinta, midabada, iyo alaabada kale ee kiimikada.Nidaamku wuxuu awood u siinaya xakamaynta saxda ah ee guryaha granul, sida cabbirka, cufnaanta, iyo porosity, hubinta tayada badeecada joogtada ah iyo sifooyinka maaraynta ee la hagaajiyay.

Warshadaha Cuntada iyo Nafaqada: Caanaha qallalan waxaa loo isticmaalaa warshadaha cuntada iyo nafaqeynta si ay u soo saaraan maaddooyinka granular, kabka cuntada, iyo cuntada lagu daro.Waxay u ogolaataa samaynta isku-dhafka caadada ah, nidaamyada sii-deynta la kantaroolo, iyo hagaajinta socodka socodka wax-ku-oolka ah iyo ku habboonaanta macaamiisha.

Metallurgy Budada: Qalalan qallalan ayaa door muhiim ah ka ciyaara biraha birta ah, halkaas oo budada birta ah la isku dhejiyo oo la isku dhejiyo si ay u sameeyaan kaydka quudinta hababka xiga sida cufnaanta, sintering, iyo qaabeynta.Gawaarida qallalan waxay wanaajisaa sifooyinka socodka, cufnaanta, iyo isku-duubnida budada birta ah, fududaynta maarayntooda iyo hawlgallada wax soo saarka ee xiga.

Gabagabo:

Granulators qallalan waxay bixiyaan granulation hufan oo kharash-ool ah oo qalab qalalan iyada oo aan loo baahnayn dareeraha dareeraha ah ama dareerayaasha.Faa'iidooyinka sida xasilloonida la wanaajiyey, kaydinta kharashka, iyo guryaha la beddeli karo, granule qallalan ayaa laga helay codsiyo warshado kala duwan, oo ay ku jiraan dawooyinka, kiimikooyinka, cuntada, nafaqeynta, iyo birta budada.Isticmaalka granulator-yada qalalan, wax-soo-saarayaashu waxay gaari karaan tayada badeecada joogtada ah, waxay wanaajiyaan sifooyinka maaraynta, waxayna sare u qaadi karaan hanaankooda wax-soo-saarka.