Nidaamka wax soo saarka granulation diskka oo dhamaystiran oo kala duwan ayaa ah mid ka mid ah faa'iidooyinka ugu muhiimsan ee Henan Zheng Heavy Industries.Waxay ku siin kartaa xalal wax soo saarka dhamaystiran oo lagu kalsoonaan karo iyadoo loo eegayo baahida dhabta ah ee macaamiisha.

Waxaan khibrad u leenahay qorsheynta iyo adeegga khadadka wax soo saarka bacriminta ee kala duwan.Ma ahan oo kaliya diiradda saaraya xiriir kasta oo geeddi-socod ee habka wax-soo-saarka, laakiin sidoo kale had iyo jeer waxaynu ogaannaa faahfaahinta geeddi-socod kasta oo ku saabsan dhammaan khadka wax-soo-saarka oo si guul leh u gaarno isku-xirnaanta.

Khadka wax soo saarka ee granulator-ka diskka waxaa inta badan loo isticmaalaa in lagu soo saaro bacriminta organic.Bacriminta dabiiciga ah waxaa laga samayn karaa xoolaha iyo digada digaaga, qashinka beeraha iyo qashinka adag ee degmada.Qashinkan dabiiciga ah wuxuu u baahan yahay in si dheeraad ah loo sii farsameeyo ka hor inta aan loo beddelin bacrimiyeyaasha dabiiciga ah ee ganacsiga ee qiimaha ganacsi ee iibka ah.Maalgelinta lagu beddelayo qashinka qashinku waa mid aad u qiimo badan.

Khadka soo saarista bacriminta dabiiciga ah ee granulated disc ayaa ku habboon:

- ►Soo saarista saxarada lo'da bacriminta dabiiciga ah

- ►Soo-saarka digada doofaarka bacriminta dabiiciga ah

- ►Soo-saarka digaaga iyo digada shinbiraha bacriminta dabiiciga ah

- ►digada idaha wax soo saarka bacriminta organic

- ►Wax soo saarka bacriminta dabiiciga ah ee dhoobada magaalada

1. digada xoolaha: digada digaaga, digada doofaarka, digada idaha, digada lo'da, digada fardaha, digada bakaylaha, iwm.

2. Qashinka warshadaha: canabka, caleenta khalka, haraaga cassava, haraaga sonkorta, qashinka bayogaas, haraaga dhogorta, iwm.

3. Qashinka beeraha: caws dalagga, bur soybean, budada cudbi, iwm.

4. Qashinka guriga: qashinka jikada

5. dhoobada: dhoobada magaalada, dhoobada webiga, dhoobada filter, iwm.

Khadka wax soo saarka granulation disk waa mid horumarsan, hufan oo wax ku ool ah, qaab dhismeedka qalabku waa mid is haysta, qalabku waa sarreeyaa, hawlgalkuna waa mid fudud, kaas oo ku habboon wax soo saarka ballaaran ee bacriminta organic.

1. Qalabka u adkaysta daxalka iyo xirashada ayaa loo isticmaalaa dhammaan qalabka wax soo saarka.Ma jiraan saddex qashin oo sii daaya, badbaadinta tamarta iyo ilaalinta deegaanka.Si tartiib ah ayay u socotaa wayna fududahay in la dayactiro.

2. Awoodda wax soo saarka ayaa lagu hagaajin karaa iyadoo loo eegayo shuruudaha macaamiisha.Nashqadaynta khadka wax soo saarka oo dhan waa mid cufan, cilmiyaysan oo macquul ah, tignoolajiyaduna waa horumarsan tahay.

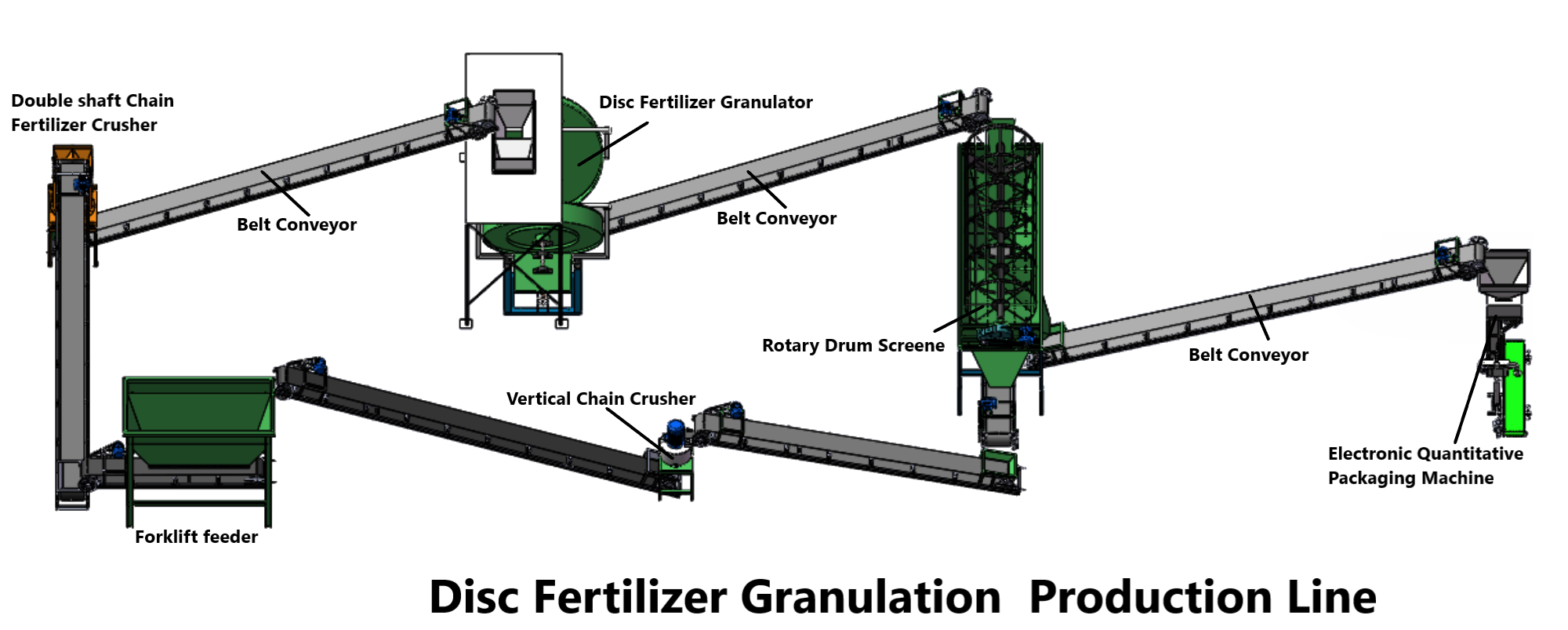

Qalabka khadka wax soo saarka ee Disk-ga waxaa ka mid ah bakhaar → blender (siring) → mashiinka granulation disk (granulator) → mashiinka shaandhada rullaluistemadka (kala soocida alaabooyinka aan tayadoodu wanaagsanayn ee alaabta la dhammeeyey) isku xidhka habab kala duwan).

Fiiro gaar ah: khadkan wax soo saarku waa tixraac kaliya.

Habka socodka ee khadka soo saarista granulation diskka waxaa badanaa loo qaybin karaa:

1. Habka maaddooyinka alaabta ceeriin

Saamiga walxaha cayriin ee adag wuxuu xaqiijin karaa waxtarka bacriminta sare.Alaabta ceeriin waxaa ka mid ah saxarada xoolaha, khudaarta qudhuntay, qolofta, khudaarta ceyriinka ah, bacriminta cagaaran, bacriminta badda, bacriminta beeraha, saddex wasakh, noole iyo walxo kale oo wasakhda dabiiciga ah.

2. Habka isku dhafka walxaha ceeriin

Dhammaan alaabta ceeriin waa la isku daray oo si siman loogu walaaqay blender.

3. Geedi socodka jabay

Burburiyaha silsiladda tooska ah wuxuu jajabiyaa qaybo waaweyn oo walxo ah qaybo yaryar oo buuxin kara shuruudaha granulation.Kadibna suunka gudbiyaha ayaa alaabta u soo diraya mishiinka granulation diskka.

4. Habka granulation

Xagasha diskka ee mashiinka granulation disk wuxuu qaataa qaab-dhismeedka arc, iyo heerka samaynta kubbadu waxay gaari kartaa in ka badan 93%.Ka dib marka maaddadu gasho saxanka granulation, iyada oo loo marayo wareegga joogtada ah ee diskka granulation iyo qalabka buufinta, maaddadu waxay si siman u wada xiran tahay si ay u soo saarto qaybo leh qaab isku mid ah iyo qaab qurux badan.

5. Habka baaritaanka

Alaabta la qaboojiyey waxaa loo raray mashiinka shaandhada rullaluleyda si loo baaro.Alaabooyinka u qalma waxay ka geli karaan bakhaarka la dhammeeyey iyada oo loo sii marayo qalabka suunka, sidoo kale si toos ah ayaa loo baakadaysan karaa.Walxaha aan u qalmin ayaa ku soo noqon doona dib u miradhalinta.

6. Habka baakaynta

Baakadu waa habka ugu dambeeya ee khadka soo saarista bacriminta organic.Alaabada la dhammeeyey waxaa lagu baakadeeyay mashiin baakad qiyaaseed oo toos ah.Heerka sare ee otomaatiga iyo waxtarka sare ma aha oo kaliya in la gaaro miisaan sax ah, laakiin sidoo kale si heer sare ah u dhammaystir habka ugu dambeeya.Isticmaalayaashu waxay xakameyn karaan xawaaraha quudinta waxayna dejin karaan cabbirrada xawaaraha si waafaqsan shuruudaha dhabta ah.